What is No. 1 Apron?

The highest quality "No. 1 AMAEKAKE," which revives the thickness that was used in the 1950s and 60s, has three major 'features'.

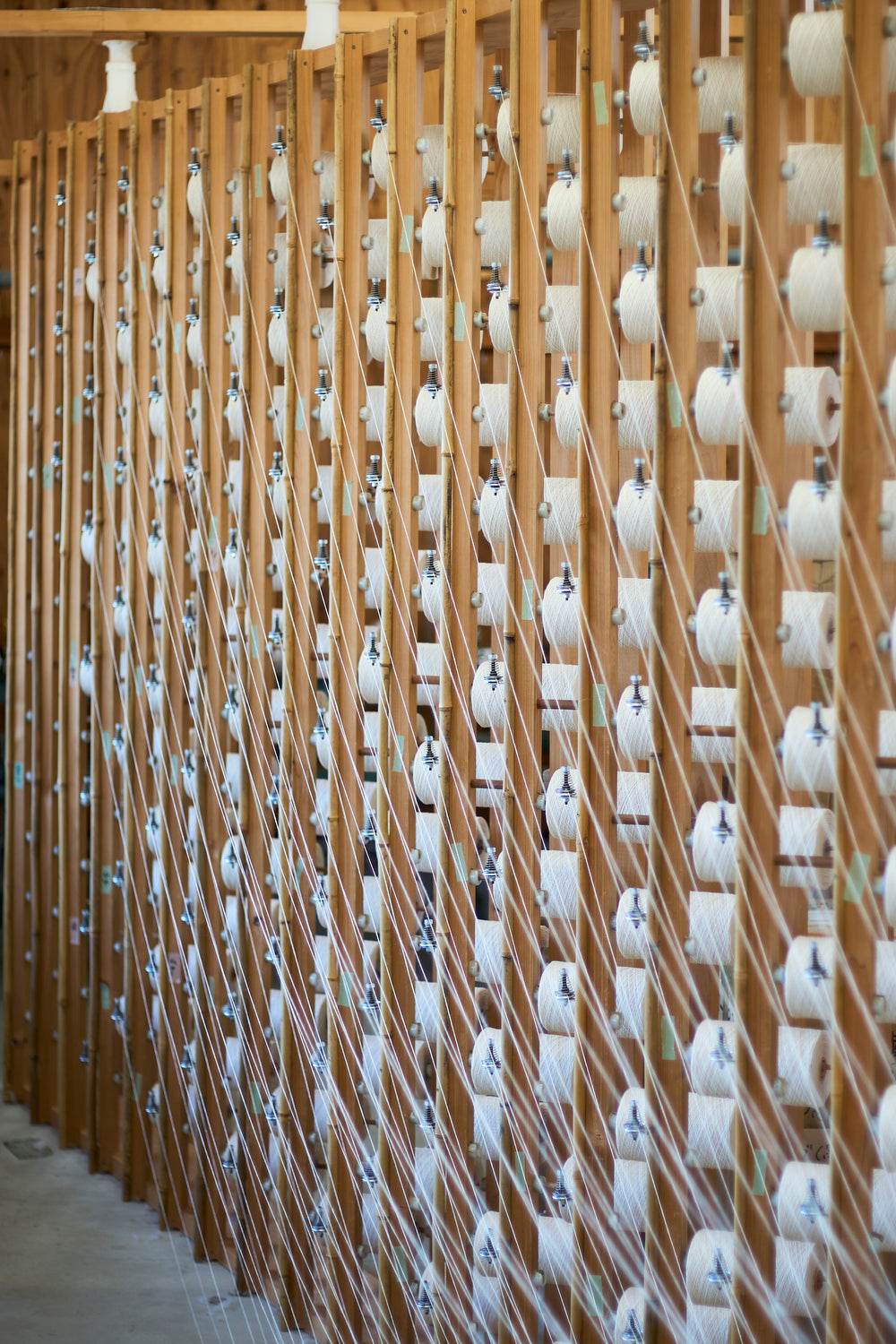

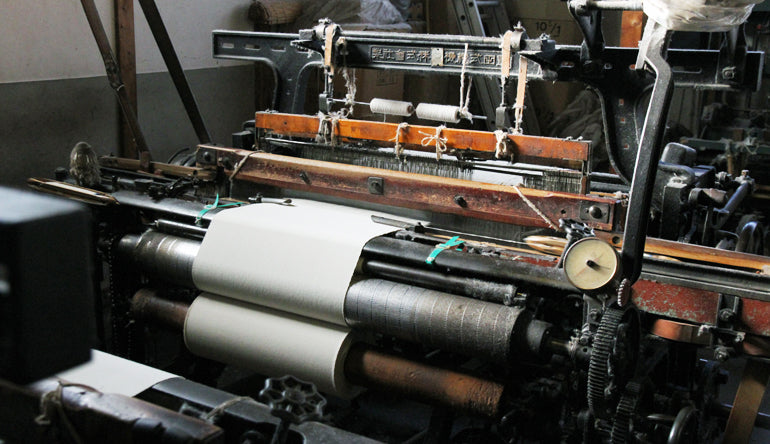

Tip 1: Weave thick fabric with thick thread!

→Using the "Shuttle Loom" invented in the Meiji to Taisho eras, the "No. 1 MAEKAKE" has been woven to bring back the original thickness of old aprons. In terms of thread count, it is woven using threads of "number four" thickness. It is also directly taught by Mr. Haga that it is possible to simultaneously achieve what seem to be contradictory things: "thick" and "soft". Its greatest feature is its thick, long-lasting fabric.

2. Soft fabric that fits the body perfectly!

→The texture of a woven fabric changes greatly depending on how the warp and weft threads are woven. Unlike ordinary "canvas", the threads and weaving method are carefully selected to create a soft fabric that naturally fits the body.

Tip 3: Traditional colors, colorfast dyes

→Dyeing thick fabrics softly with almost no color fading. Anything's dyed fabrics maintain a high ranking in washing fastness tests. Dyeing is mainly done in Tokyo.

Let's take a look at some other features of the Anything Apron.